Safety wire locking is the method to lock the nut in place after tightening with the bolt using a lock wire. A piece of stainless steel wire passes through a hole in the nut and gives a lock wire load to the nut and other ends tighten to the body. So the nut will not get loose itself.

Safety wire locking is the most positive and satisfactory method of safetying cap screws, studs, nuts, bolt heads, and turnbuckle barrels, which cannot be safely tied by any other practical means. It is a method of wiring together two or more units in such a manner that any tendency of one to loosen is counteracted by the tightening of the wire.

What is Safety Wire

Safety wire is a wire used to prevent bolts, screws, nuts, and other types of fasteners from loosening. It is usually made of stainless steel but is also available in Monel and Inconel alloys for high-temperature applications and Copper for break-away applications.

Lock Wire Material Specification

NASM20995(..)

- CRES – C

- MONEL – NC

- INCONEL – N

- Copper – CY

Safetying Emergency Equipment

For safetying emergency equipment, always use copper or brass wire.

Never use stainless steel, monel, carbon steel, or aluminum alloy safety lock wire to secure emergency mechanisms such as switch handles, guards covering handles used on exits, fire extinguishers, emergency gear releases, or other emergency equipment.

Some existing structural equipment or emergency devices for the safety of flight require copper or brass safety wire (0.015 to .020 inch diameter only), where the successful emergency operation of the equipment is dependent on shearing or breaking of the safety wire.

Particular care should be used to ensure that safetying does not prevent emergency operations.

Safety wire locking method

There are two methods of safety wiring –

- Double wire method

- Single wire method

The double wire method that is most commonly used.

Single wire method used on screws, bolts, and/or nuts in a closely-spaced or closed-geometrical pattern such as a triangle, square, rectangle, or circle. The single wire method may also be used on parts in electrical systems and in places that are difficult to reach.

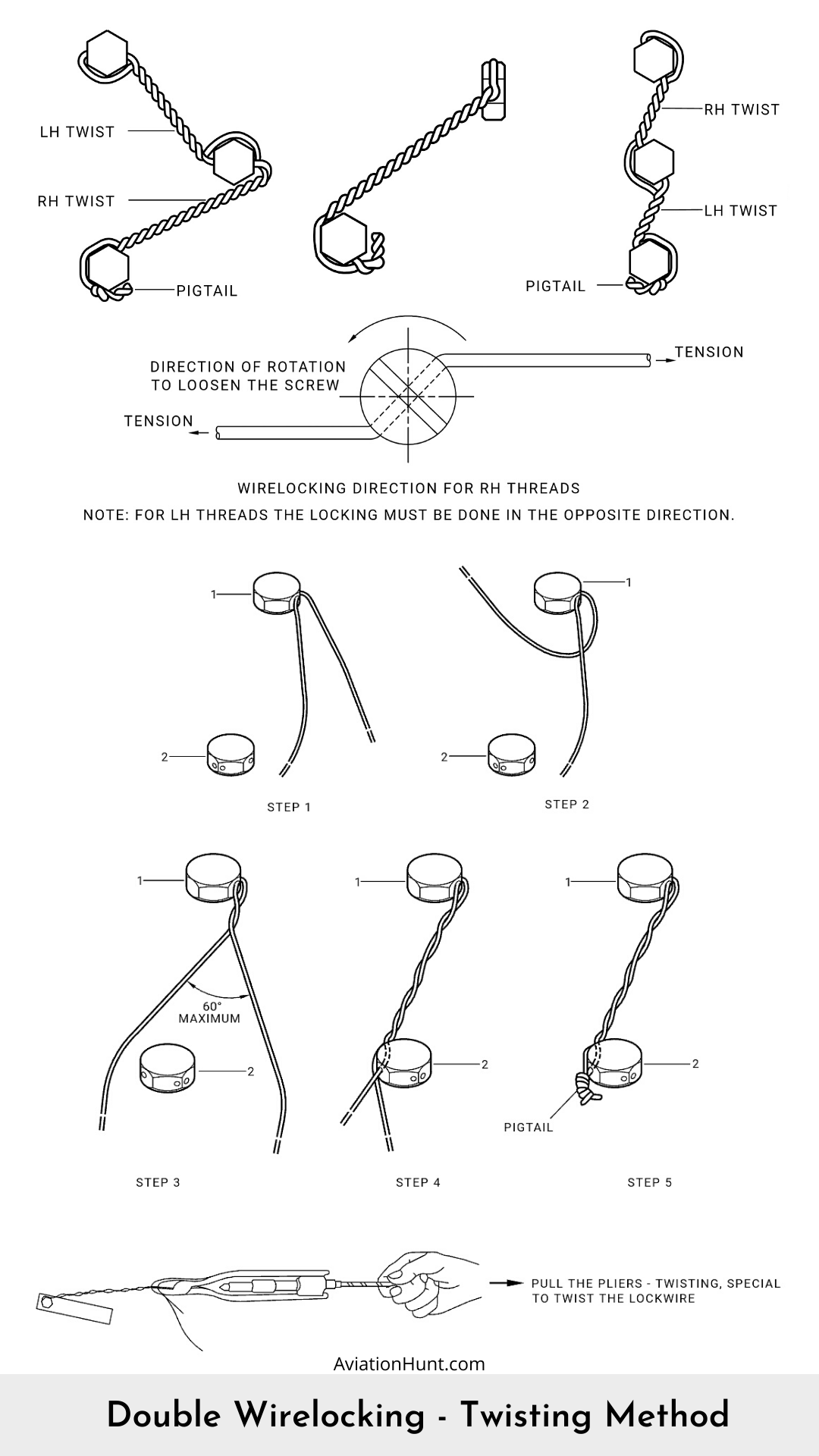

When using the double wire twisting method of safety wiring, .032 inch minimum diameter wire should be used on parts that have a hole diameter larger than .045 inch. Safety wire of .020 inch diameter (double strand) may be used on parts having a nominal hole diameter between .045 and .062 inch with a spacing between parts of less than 2 inches.

When using the single wire method, the largest size wire that the hole will accommodate should be used. Copper wire (.020 inch diameter), aluminum wire (.031 inch diameter), or other similar wire called for in specific technical orders, should be used as seals on equipment such as first-aid kits, portable fire extinguishers, emergency valves, or oxygen regulators.

Importance of safety wire locking on aircraft

Safety wire locking can save your life and helps in aviation safety.

The lockwire is installed to put tension on the wire when the parts become loose.

Loose hardware or components have led to accidents, many of them fatal. Safety wire is necessary in areas where a bolt could loosen during vibration. Used properly, it will lock so that the wire remains taut and prevents further movement. Think of it as wearing a belt with your suspenders.

Safety wire is not intended to take the place of the proper installation of fasteners. Always make sure that the fasteners or components are tightened to the proper torque first, then install the safety wire.

Safety wire must never be overstressed. It will break under vibrations if twisted too tightly. Safety wire must be pulled taut when being twisted, and maintain a light tension when secured.

Safety wire ends must be bent under and inward toward the part to avoid sharp or projecting ends, which might present a safety hazard.

General Safety Wire Locking Rules

When using the safety wire method of safetying, the following general rules should be followed:

- Use lock wire only one time and make sure that it is not damaged.

- When you install lock wire, make sure that there will not be chafing or fatigue. This is to prevent damage to the lock wire or adjacent parts. The causes of chafing or damage are vibrations or increased tension on the wire to prevent the loosening of the locked items.

- The length of the wire between the attachment points must be as short as possible.

- When you safetying with lock wire in the fuel tank areas, make sure that there is no protrusion of the wire ends:

- For the single wire method, you must twist the wire end with protrusion back to the wire.

- For the double wire method, you must bend the wire ends with protrusion back to the wire or the part that you lock (e.g. screw/nut).

- The line of approach of the lock wire must be approximately tangential to the parts that you will lock.

- When you install the lock wire, the strand that goes through the hole will tighten the locked item.

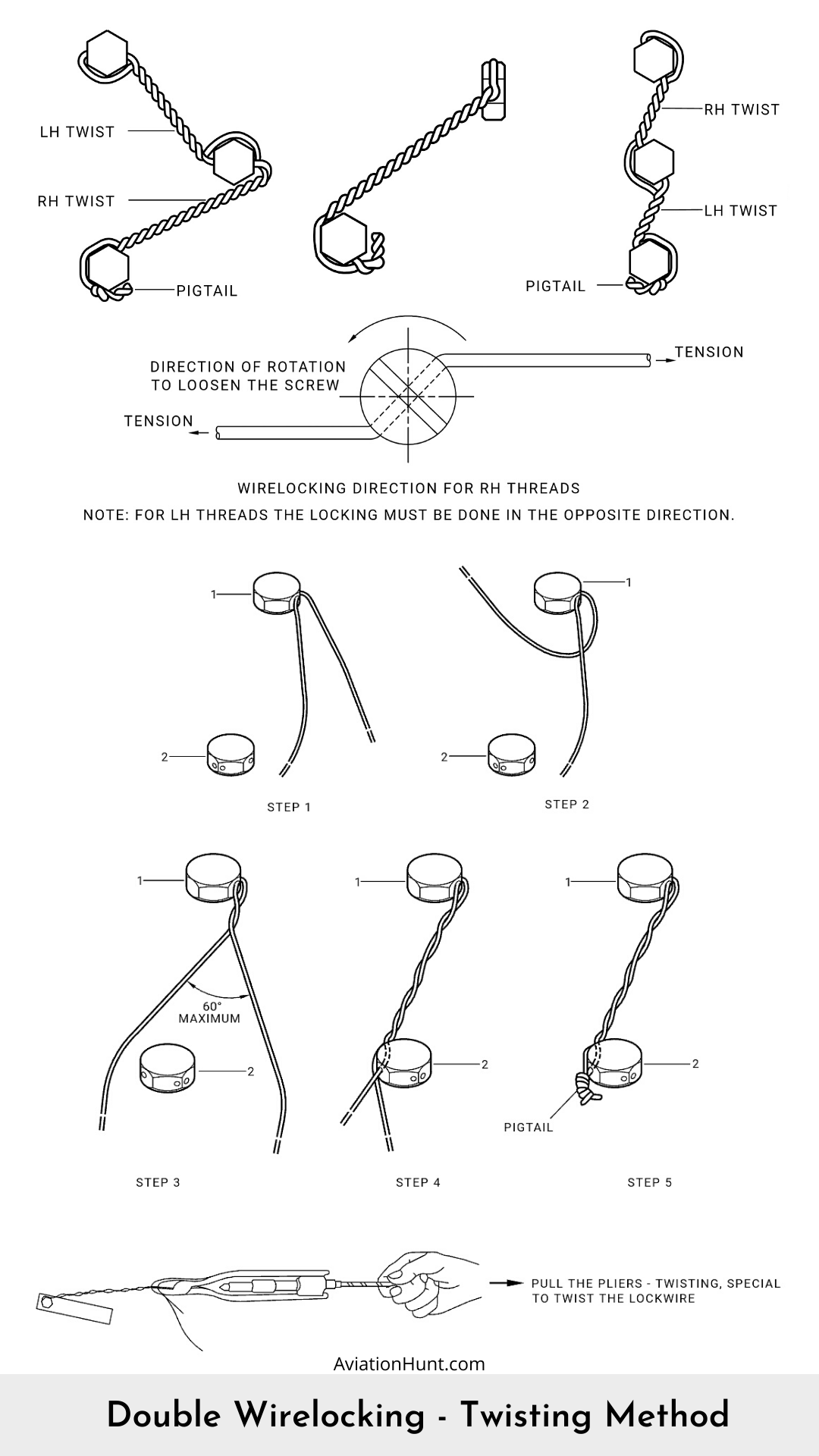

- It is important to identify items with left-hand and right-hand threads carefully before start wire locking.

- When you use an anchor lug, the wiring must start at the lug and the lug must align with the wire. The wire must not cause radial movement of the lug.

- The recommended method is the “double wire twisting method“.

- The maximum distance between fasteners should be 100 mm (3.94 in.).

- If the distance is more than 100 mm (3.94 in.) – use one more attachment point.

- The maximum length of the wire should be 600 mm (23.62 in.).

- You can safetying a maximum of 3 items together with a lock wire.

Precautions Before Wire Locking

- Make sure that all lock wire holes are drilled.

- Make sure that the assembly was torqued to the requirements of the related task.

- Use SPECIAL TWISTING PLIERS, to twist the lock wire clockwise at a maximum angle of 60° and Do not put too much tension on the wire.

- Keep the lock wire tight during the twisting, until the twisted part comes very near to the hole in the next unit.

- The direction of the wrap and the twisted strands must be such that the loop around the part comes below the strands that go out of the hole. Thus the loop will stay down and will not become loose.

- Twist the strands in the direction that will cause the lower lock wire to always be pulled down.

- A pigtail of 1⁄4 to 1⁄2 inch (three to six twists) should be made at the end of the wiring. Some aircraft manufacturer recommends that the length of the twisted part (pigtail) must be between 10 mm to 15 mm.

- If necessary, cut and discard the unwanted length of lock wire and you must collect the cut-off material to prevent damage to the aircraft.

- Bend the pigtail around the fastener head.

- When you safetying with lock wire in the fuel tank areas, make sure that you bend the wire ends with protrusion along the wires. You must also make sure that the wire ends stay near to the wire or the part that you lock.

- Make sure that there are no signs of damage (nicks, kinks) on the lock wire.

Use these types of wires for lock wire

- Use monel, inconel, or corrosion-resistant lock wire in high-temperature areas.

- Use copper wire, 0.015 in. (0.381 mm) in diameter, on emergency equipment only.

- Use Clad 5056 aluminum alloy wire for lock wire that touches magnesium to prevent galvanic corrosion.

NOTE: Use copper wire where a seal is necessary on emergency equipment to show no person has used the equipment. Emergency equipment includes portable fire extinguishers, first aid kits, emergency valves, and oxygen regulators.

Safety wire twister

A safety wire twister is a tool that allows the user to grip the two loose ends of a piece of safety wire in order to twist the safety wire.

Twist the wire with a wire twister as follows –

- Grip the wire in the jaws of the wire twister and slide the outer sleeve down with your thumb to lock the handles or lock the spring-loaded pin.

- Pull the knob, and the spiral rod spins and twists the wire.

- Squeeze handles together to release wire.

When using wire twisters, and the wire extends 3 inches beyond the jaws of the twisters, loosely wrap the wire around the pliers to prevent whipping and possible personal injury. Excessive twisting of the wire will weaken the wire.

Diameter of lock wire vs number of twists

- Less than 0.019 inch dia – 11 to 14 twist per inch

- 0.019 to 0.026 inch dia – 9 to 12 twist per inch

- 0.023 to 0.042 inch dia – 7 to 10 twist per inch

- 0.043 to 0.065 inch dia – 5 to 8 twist per inch

- More than 0.065 inch dia – 4 to 7 twist per inch